An effective way to contribute to any workshop or construction site is to have a reliable rivet tool kit on hand. Riveting, a joining process, uses a rivet – a cylindrical metal piece with one end having a head – placed into two materials in order to lock them together. It works particularly well when the two objects have a sizeable gap that needs to be bridged such as connecting frame materials together, or attaching components to a car chassis for example.

Solid rivets stand out among all other rivets due to their unparalleled strength and immense durability, making them the number one choice for applications that are under immense stress and pressure, such as those within the automotive and aerospace industries. For crafting strong connections with these rivets, one needs to purchase a rivet tool kit.

To guarantee a secure bond, a solid rivet tool kit must always include a rivet gun. This device, either electric- or pneumatic-powered, provides the pressure necessary for the rivet to expand. Furthermore, in order to provide integrity while expanding, a bucking bar–which is a hefty metallic input–should be employed. Finally, with the use of a rivet setter to determine the correct depth for the rivet in its place, all components of the kit are then in sync.

To ensure proper assembly, a solid rivet tool kit is comprised of an array of rivets in assorted sizes and materials. When picking the ideal rivet, it is crucial to select one which is best suited to the task at hand. Rivet options include aluminium, steel, and stainless steel of varying diameters and lengths. In addition to the rivets, said tool kit will also come with a rivet gun, bucking bar, and rivet setter.

A necessary addition to any equipment set for riveting is a solid rivet tool kit, containing helpful tools like the rivet stop to stop a rivet from over-expanding and causing harm to the material it is holding together. As well, they should be supplied with a brush to brush away any debris from the attachment site and a gage to guage the size of the rivet prior to installation. Essential components in the kit are an anvil for compressing the head of the rivet once it has been put in place, as well as a washer which acts as a guide to ensure proper placement of the rivet.

If you need to securely and durably join two materials together, a solid rivet tool kit is the way forward. This handy and invaluable set of tools and rivets makes any workshop or construction site prepared for joining work, and is an incredibly wise investment for any business that requires regular riveting.

Riveting plays a critical role in many industrial operations, and having the right tools for the task is essential for a successful rivet job. A solid rivet tool set is a collection of instruments and additions specifically crafted together to simplify and expedite riveting. To get an idea of how a full-fledged solid rivet toolkit can operationalize productivity, this article dives into the components of such a kit and their usage.

The essential components of a reliable rivet tool kit include various tools, attachments, and extras to ensure successful riveting. Pneumatic, manual, and battery-powered rivet guns are a given for working the rivets in place. Also included is a range of rivet sets, including standard to countersunk, which are used to make the hole which the rivets will be inserted into. Furthermore, the kit has an array of accompanying accessories including drill bits, punches, and wrenches to prepare the workpiece. Finally, any variety of drill bits and extra attachments needed to provide a secure hold for the rivets in the workpiece are provided in the kit.

Making riveting a breeze can be achieved with the right toolkit. Start by selecting a suitable rivet gun to apply the job – manual, pneumatic, and even battery-powered models are all available. Then, it’s important to carefully prepare the workpiece for the rivets, which requires drilling diamond-shaped holes that are the precise size for the rivets. If the holes are too minuscule, insertion may not even be possible. On the opposite end of the spectrum, if they’re too wide, the rivet will rattle around aimlessly instead of providing an effective fit.

After the holes have been made, you need to create a base for insertion of the rivets. This is done through using rivet sets, like a jigsaw puzzle, which come in varying shapes and sizes so that any kind of rivet will fit. Once everything is settled, fire up the rivet gun and drive the rivets in. Make sure to press them all with the same intensity so that they all fit snug and securely.

Alongside the rivet gun and sets, the complete solid rivet tool set often comes with supplementary pieces. These extra parts can range from wrenches to punches and drill bits which enable one to ready the surface for riveting. In addition to this, drill bits and diversified attachments are commonly included in these kits to make simple work of drilling the holes into the material which will later be filled by the rivets.

Riveting doesn’t have to be a complicated endeavor – with the proper solid rivet tool kit, it can be executed efficiently and accurately. All that is required is opting for the best tools for the job, prepping the workpiece accurately, and making use of the appropriate rivet sets. Additionally, the additional accessories and attachments provided by the kit can make riveting an accelerated process. Therefore, by selecting the right toolkit, you can turn riveting into a hassle-free job.

Post time: 2023-08-07

Related Product

Solar panel

PV Kits for fields, flat and pitched roofs The kit using photovoltaic support system is critical to photovoltaic support, including wind calculation speed, order picking speed and […]

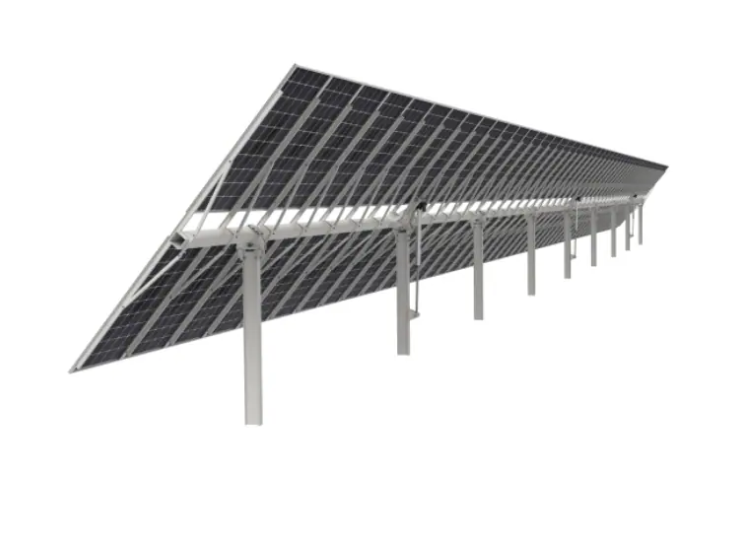

GROUND MOUNT PV Support

Placement position Ground Applicable component type Framed or frameless solar panels of various sizes Raw materials of support aluminium alloy Installation angle According t […]

PV support KITS

What is Cable conduit? A metal protective tube with certain mechanical strength laid on the outer layer of the cable to prevent the cable from being damaged Cable threading […]

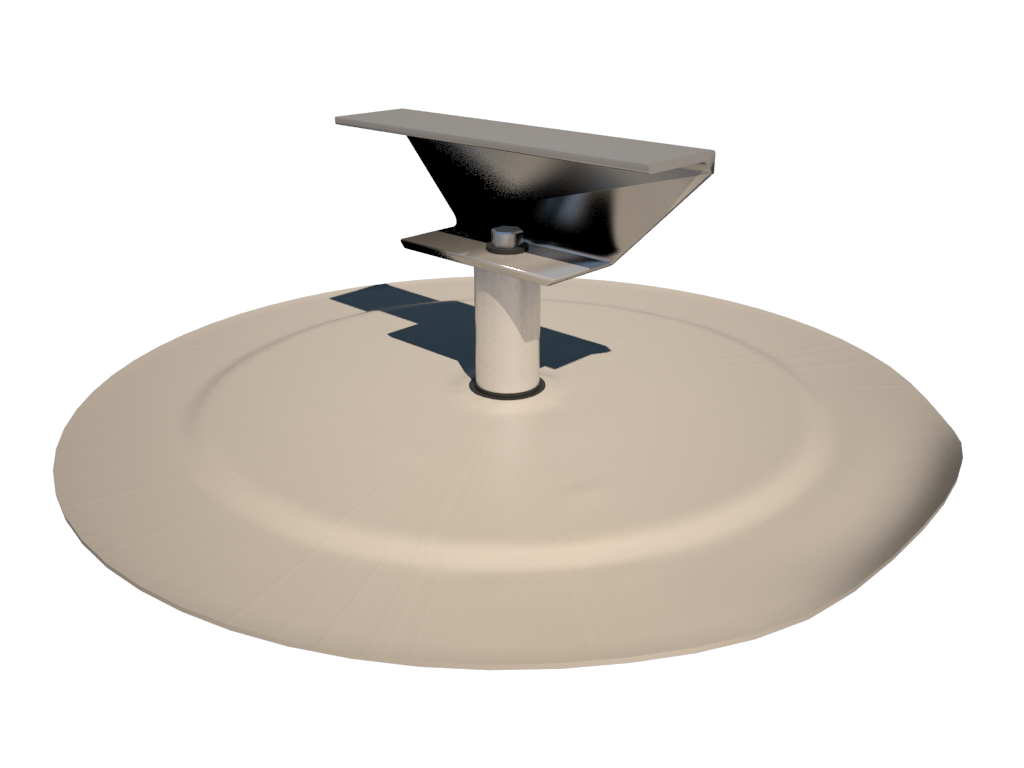

Flat roof photovoltaic support

Flat roof photovoltaic support Analysis of installation and construction problems of flat roof photovoltaic power station The external roof system on the roo […]

PV bridge support

Features of PV bridge support products: Strong resistance to negative wind pressure, good stability, strong bearing capacity and strong lateral tensile capacity; Easy and fast ins […]

Inclined roof photovoltaic support

V support system for inclined roof The inclined roof installation system is suitable for all kinds of inclined roofs. According to the roof bearing capacity and waterproof requirem […]

PV inverter

PV inverter (PV inverter or solar inverter) can convert variable DC voltage generated by photovoltaic (PV) solar panel into AC inverter of mains frequency, which can be fed back to […]

PV bracket tracking system

Ground tracking photovoltaic support Fully adapt to 210 major components The product has been tested in CPP wind tunnel Use AI algorithm to optimize tracking mode Irregular land is […]