For a strong and lightweight solution, the 1.5×1.5 steel tube is the perfect choice. Oftentimes, structures such as constructions benefit from this size because of the reduced weight it allows. It’s outer and inner diameter measure to be 1.5 inches respectively, with a wall thickness that is usually 0.065 inches thick, yet can differ as per the manufacturer.

Purchasing and working with a 1.5×1.5 steel tube is a breeze! You can readily find this size option at both online and brick-and-mortar retailers and many times, it’s surprisingly cost-effective. For those looking to save, this piece is perfect. Plus, due to its size, manipulating the tube is easier than ever. Whether you’re looking to drill, cut or weld it, you can complete your DIY project with ease.

Opting for a 1.5×1.5 size of steel tube requires taking into consideration the purpose it is put to. Assuming the tube is exposed to nature’s elements, it should be crafted from an alloy that can endure these weather conditions. But if the tube entails a heavy workload, then a higher grade of steel must be procured for reliable endurance. With a variety of high-strength steel grades accessible, one is able to select the right one that is suited for their application.

After selecting the correct grade of steel, it is time to move onto cutting the tube. This presents an array of options – power saws are generally the preferred choice here. If the tube will bear any sort of load, attention must be gravitated to gauging the squareness of its ends. Last but not least, after completion of cutting, drilling and welding processes can go ahead as necessary.

For projects requiring strength and stability without considerable heft, using a 1.5 x 1.5 steel tube is a stellar solution. Easy to locate and cost-effective, this size steel tube is also amenable to do-it-yourself projects. When selecting a tube, be mindful of its intended purpose and choose the grade of steel accordingly. Moreover, you can trim the tube to the desired length before drilling and welding as necessary.

Post time: 2023-06-26

Related Product

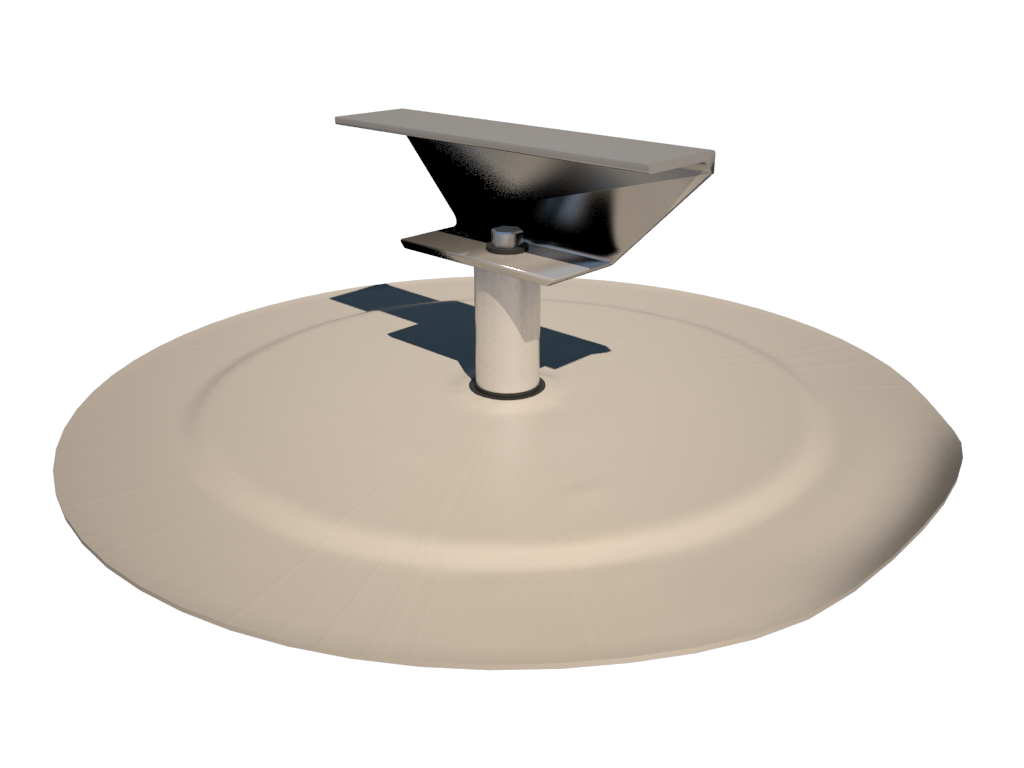

Flat roof photovoltaic support

Flat roof photovoltaic support Analysis of installation and construction problems of flat roof photovoltaic power station The external roof system on the roo […]

PV support KITS

What is Cable conduit? A metal protective tube with certain mechanical strength laid on the outer layer of the cable to prevent the cable from being damaged Cable threading […]

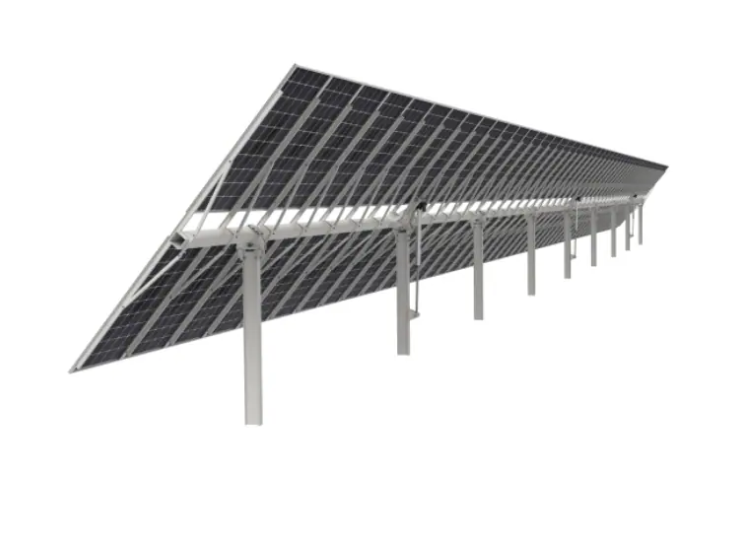

GROUND MOUNT PV Support

Placement position Ground Applicable component type Framed or frameless solar panels of various sizes Raw materials of support aluminium alloy Installation angle According t […]

Solar panel

PV Kits for fields, flat and pitched roofs The kit using photovoltaic support system is critical to photovoltaic support, including wind calculation speed, order picking speed and […]

Inclined roof photovoltaic support

V support system for inclined roof The inclined roof installation system is suitable for all kinds of inclined roofs. According to the roof bearing capacity and waterproof requirem […]

PV bracket tracking system

Ground tracking photovoltaic support Fully adapt to 210 major components The product has been tested in CPP wind tunnel Use AI algorithm to optimize tracking mode Irregular land is […]

PV bridge support

Features of PV bridge support products: Strong resistance to negative wind pressure, good stability, strong bearing capacity and strong lateral tensile capacity; Easy and fast ins […]

PV inverter

PV inverter (PV inverter or solar inverter) can convert variable DC voltage generated by photovoltaic (PV) solar panel into AC inverter of mains frequency, which can be fed back to […]