Drivers of the dependable Toyota Tundra may be surprised to learn that its independent front suspension (IFS) is not perfect. While it delivers a smooth ride on roads, the IFS struggles with the stress of off-roading. To fortify their truck, many Tundra owners have made the switch to a solid axle system.

Completing a solid axle swap (SAS) on a Tundra may seem quite daunting, yet it is within reach of most DIYers. Looking to help out such ambitious people, several companies have put together SAS kits which include all of the necessities for the job.

One of the major upsides of having a solid axle suspension (SAS) is the ability to fit bigger wheels on the vehicle. Moreover, the added ground clearance it offers is perfect when tackling rough terrain. Take it off-roading and rest assured that its design is sure to withstand more wear and tear than your conventional independent front suspension (IFS).

Undertaking a SAS isn’t a simple task. You’ll need to be sure you have the skills to tinker with your vehicle and an understanding of custom fabrication. It is crucial to remember that this project will void out any manufacturer warranties.

Taking on these tasks is no small job, and if you’re looking to apply a SAS to your Tundra, then awareness of what is necessary is important. Don’t forget that the modifications would negate that privileged factory warranty – so be sure you’re adept in performing the necessary duties. As custom fabrication may be required, ensure you feel comfortable with taking it on before anything else.

A successful solid axle swap for any Tundra is not impossible, provided the DIY-er has the necessary knowledge and experience. Most companies can provide complete kits to make the job easier and provide additional guidance. Nevertheless, the individual should be aware that performing the swap could possibly void warranties from the factory, so it may be wise to make sure they are comfortable and well-informed about the process before they commence.

Post time: 2023-07-01

Related Product

GROUND MOUNT PV Support

Placement position Ground Applicable component type Framed or frameless solar panels of various sizes Raw materials of support aluminium alloy Installation angle According t […]

Flat roof photovoltaic support

Flat roof photovoltaic support Analysis of installation and construction problems of flat roof photovoltaic power station The external roof system on the roo […]

Solar panel

PV Kits for fields, flat and pitched roofs The kit using photovoltaic support system is critical to photovoltaic support, including wind calculation speed, order picking speed and […]

PV inverter

PV inverter (PV inverter or solar inverter) can convert variable DC voltage generated by photovoltaic (PV) solar panel into AC inverter of mains frequency, which can be fed back to […]

PV support KITS

What is Cable conduit? A metal protective tube with certain mechanical strength laid on the outer layer of the cable to prevent the cable from being damaged Cable threading […]

Inclined roof photovoltaic support

V support system for inclined roof The inclined roof installation system is suitable for all kinds of inclined roofs. According to the roof bearing capacity and waterproof requirem […]

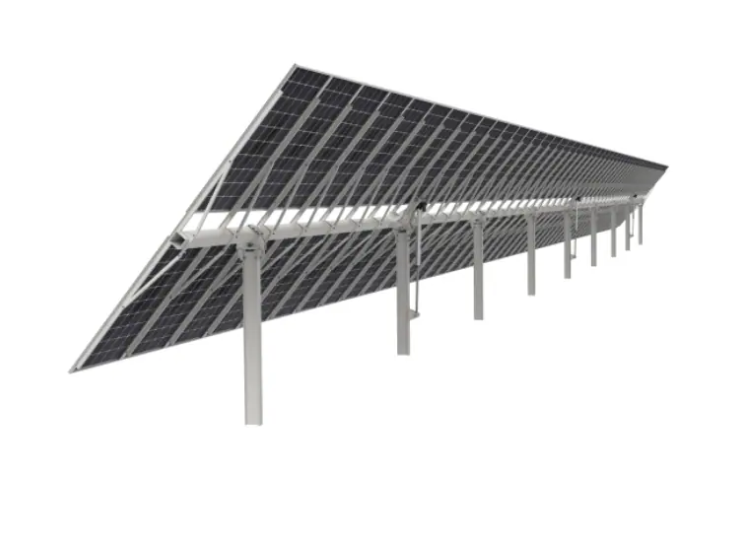

PV bridge support

Features of PV bridge support products: Strong resistance to negative wind pressure, good stability, strong bearing capacity and strong lateral tensile capacity; Easy and fast ins […]

PV bracket tracking system

Ground tracking photovoltaic support Fully adapt to 210 major components The product has been tested in CPP wind tunnel Use AI algorithm to optimize tracking mode Irregular land is […]